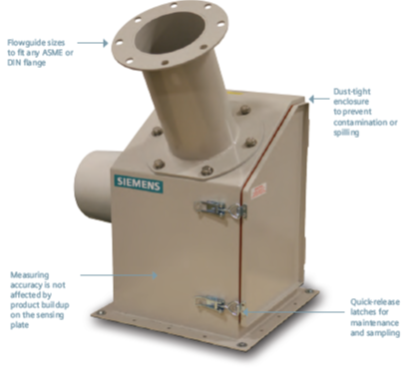

SOLIDS FLOWMETERS는 수직 이송물의 유량을 측정하는

장비입니다. 밀폐형 구조로 설계되어 원료의 누수가 없으며

유지보수가 용이하며 위험 지역에서의 적합한 환경을

제공합니다.

원료의 브릿지나 적체에 영향을 받지 않으며

원료가 떨어지는 수직 방향에 대해서만 감지를 합니다.

Sensing heads type, Sensing Plates type, LVDT type등의

모델을 제공합니다.

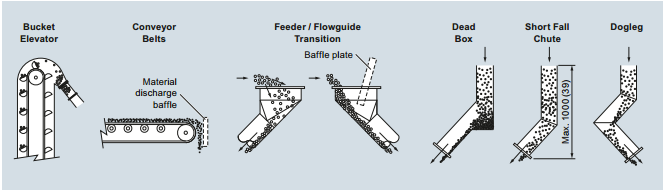

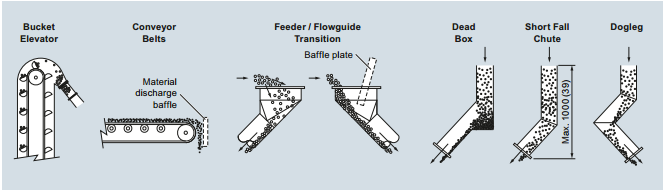

SITRANS WF solids flowmeters monitor the rate of bulk material

flow in a process. They continuously measure the impact force

of the material under gravity feed conditions, and convert this

signal into a flow rate used to control the rate into a process or

blending operation.

Solids flowmeters can function in standalone measuring operations, or they can interface to a facility’s

process control system using industry standard protocols

SOLIDS FLOWMETERS는 수직 이송물의 유량을 측정하는

장비입니다. 밀폐형 구조로 설계되어 원료의 누수가 없으며

유지보수가 용이하며 위험 지역에서의 적합한 환경을

제공합니다.

원료의 브릿지나 적체에 영향을 받지 않으며

원료가 떨어지는 수직 방향에 대해서만 감지를 합니다.

Sensing heads type, Sensing Plates type, LVDT type등의

모델을 제공합니다.

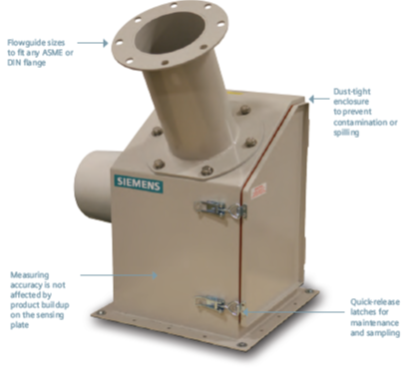

SITRANS WF100 flowmeter is a low to medium capacity flowmeter for various product sizes, densities, and fluidities in restricted spaces.

WF100 is unaffected by corrosive, abrasive, or hot materials.

Handling various product sizes, densities, and fluidities including fine powders such as sugar, the WF100 helps to improve final product, increase operating efficiency, and realize significant

cost savings.

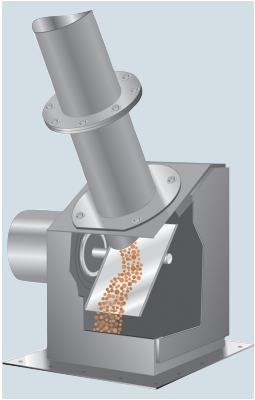

Dry bulk solids enter the flow guide producing a mechanical deflection as they strike the flowmeter sensing plate before continuing through the process un-hindered. The WF100 converts

the deflection into an electrical signal that feeds into an accompanying integrator, which instantaneously displays the flow rate

and totalizes the weight.

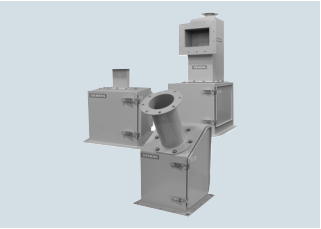

SITRANS WF200 and WF250 flowmeters are medium to high capacity flowmeters for various product sizes, densities, and fluidities.

Operating with a microprocessor based integrator package, the

WF200 series flowmeters display flow rate, totalized flow, and

rate alarms. Outputs are 0/4 to 20 mA proportional to rate and

contact closure for remote totalization. Dry bulk solids enter the

flowmeter before continuing through the process unhindered.

The load cells convert the horizontal force of the deflection into

an electrical signal. The integrator processes this into flowrate

and integrated total weight. The sensing process is immune to

the effect of product build-up as only the horizontal force is measured.

With load cells located externally to the process, the WF200 series flowmeters measure high capacities with a maximum rate of

900 t/h (990 STPH). For high capacity aerated gravity conveyor

pre-feed, the WF250 has a maximum rate of 900 t/h (990 STPH).

SITRANS WF300 series are low to medium capacity flowmeters for various product sizes, densities, and fluidities.

With weighing mechanics located externally, the WF300 series

solids flowmeters are unaffected by corrosive, abrasive, or hot

materials. Handling a wide range of product sizes, densities,

and fluidities including fine powders such as cement, they operate at process temperatures to 230 °C (450 °F). The flowmeters

help to improve final product, increase operating efficiency, and

realize significant cost savings.

Operating with the appropriate SITRANS WFS sensing head and

a micro-processor-based integrator package, the WF300 series

flowmeters provide a display of the flow rate, totalized flow, and

alarms. Outputs are 0/4 to 20 mA proportional to rate, and open

collector output for remote totalization.

Dry bulk solids enter the flow guide producing a mechanical deflection as they strike the flowmeter sensing plate before continuing through the process unhindered. The LVDT in the sensing head converts the deflection of the horizontal force into an

electrical signal. The integrator processes this signal into a display of flowrate and integrated total weight. The weighing process is immune to the effect of product build-up as only the horizontal force is measured.

SITRANS WF330 flowmeters are totally enclosed, with external

weighing mechanics, operating with corrosive, abrasive or hot

materials. SITRANS WF350 series operates with aerated gravity

conveyors, and includes integral vents and baffles for air separation. For applications with little available headroom, the

SITRANS WF340 series flowmeters provide the answer.

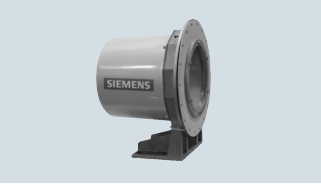

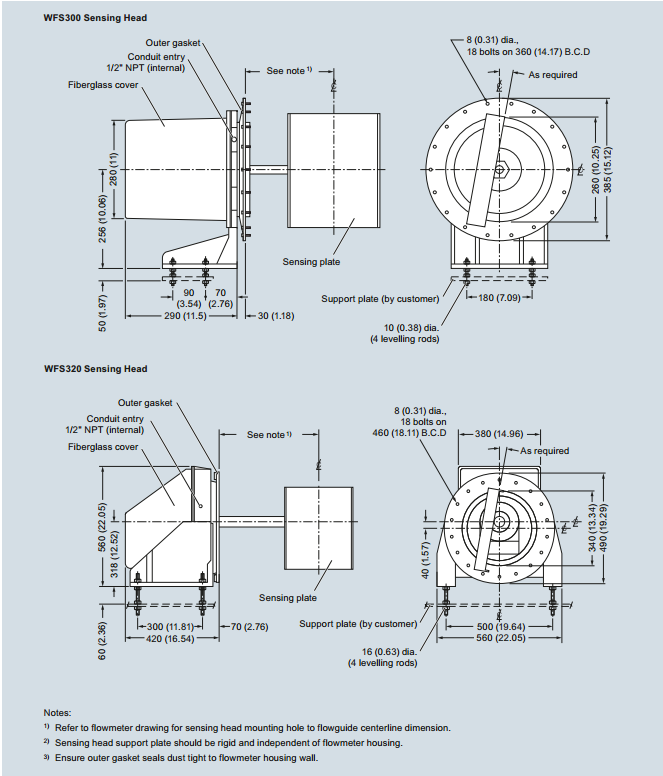

SITRANS WFS300 and WFS320 sensing heads are out-of-the process sensing elements for SITRANS WF300 series solids flowmeters.

SITRANS WFS300 and WFS320 sensing heads are used in applications such as product rationing, batch load-out, and process feed rate control, the WFS series of sensing heads has

been field-proven in thousands of applications with some units

providing over a quarter century of reliable performance.

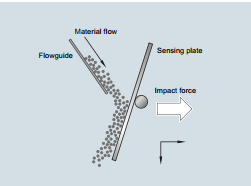

The WFS sensing heads use only the horizontal force created by

impact of product upon the sensing plate and then apply the

horizontal deflection to a highly reliable linear variable differential

transformer (LVDT).

Friction-less pivots exclude the vertical force from the sensing

process and the LVDT travel range is controlled by a coil spring

selected for the specified full-scale flow rate. A viscous fluid

damper provides mechanical damping in the event of pulsating

flows.

The LVDT converts the horizontal movement, proportional to the

impact forces into an electrical signal, which is converted by the

integrator to time-based flow rate indication and totaling. This

method of sensing material flow has been proven best in thousands of applications all over the world.

WFS300 series sensing head dimensions in mm (inch)

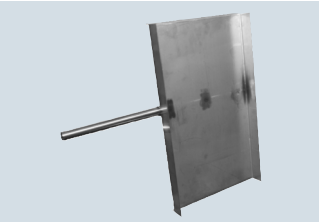

The sensing plate transfers the impact force to the sensing head of the flowmeter.

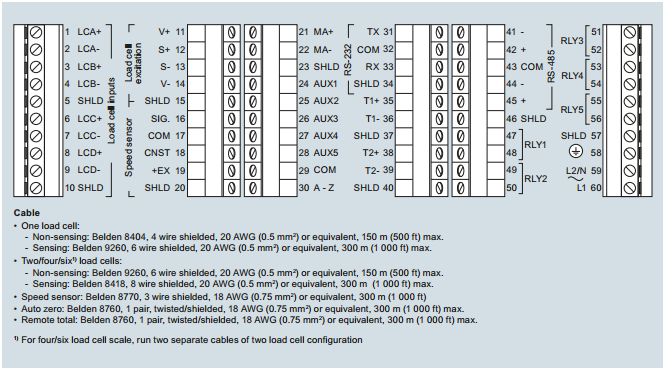

Milltronics BW500 is a full feature integrator for use with both belt

scales and weighfeeders.

Milltronics BW500/L is an integrator for use in basic belt scale or

weighbelt applications.

Milltronics BW500 and BW500/L operate with a belt scale and a

speed sensor. Belt load and speed signals are processed for accurate flow rate and totalized weight of bulk solids.

BW500 can take on lower level control functions traditionally

handled by other devices, and it supports popular industrial

communication buses. Its proven load cell balance function

eliminates matching of load cells.

The PID function may be used for rate control on shearing weighfeeders - where belt loading is constant - but can also control

pre-feeding devices. Operating in tandem with two or more

weighfeeders, the BW500 may be used for ratio blending and

controlling additives. Batching, load out, and alarm functions are

also provided by the BW500.

Dolphin Plus software may be used for programming the unit on

a PC.

| BW500(advanced feature set) | BW500/L(basic feature set) | |

|---|---|---|

| PID control | With optional I/O card | N/A |

| Differential speed detection | Standard | N/A |

| Online calibration | Standard | N/A |

| Trade approval (OIML, MID, Measurement Canada, GOST, NTEP) | Optional | N/A |

| SmartLinx communications (DeviceNET, ProfiNet, Modbus, TCP/IP, EtherNet/IP, and Profibus DP) | Optional | Optional |

| Modbus | Standard | Standard |

| Ratio Blending and Batching | Standard | N/A |

| Moisture and incline compensation |

With optional I/O card, or Parameter set |

Parameter set |

| Multi Span | Standard | N/A |

| RD500 connectivity | Standard | Standard |

| Relay output | 5 | 2 |

| Time/date stamped printing | Standard | N/A |

| mA output | 3 | 1 |

| mA input | 2 | 0 |

Milltronics BW500 and BW500/L dimensions in mm (inch)

Milltronics BW500 and BW500/L connections