Application

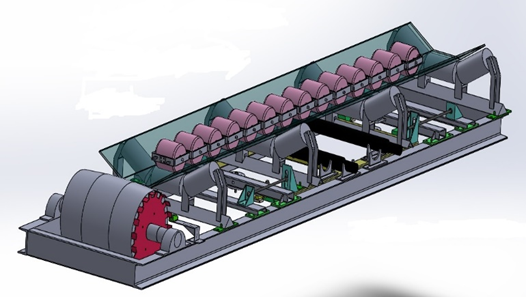

Milltronics MSI belt scale

Milltronics MSI belt scale provides continuous in-line weighing

on a variety of products in primary and secondary industries. It

is proven in a wide range of tough applications from extraction

(in mines, quarries and pits), to power generation, iron and steel,

food processing and chemicals. The MSI is suitable for monitoring such diverse products as sand, flour, coal, or sugar.

The MSI’s proven use of parallelogram-style load cells results in

fast reaction to vertical forces, ensuring instant response to

product loading. This enables it to provide outstanding accuracy

and repeatability even with uneven loading and fast belt speeds.

Operating with Milltronics BW500, or SIWAREX FTC microprocessor-based integrators, the MSI provides indication of flow

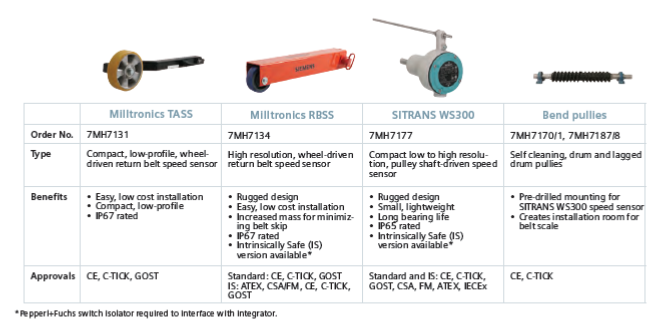

rate, totalized weight, belt load, and belt speed of bulk solid materials. A speed sensor monitors conveyor belt speed for input to

the integrator.

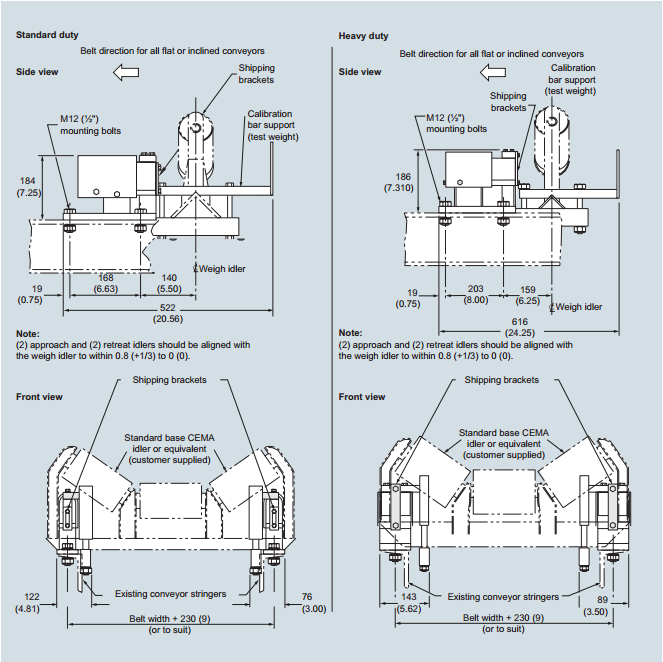

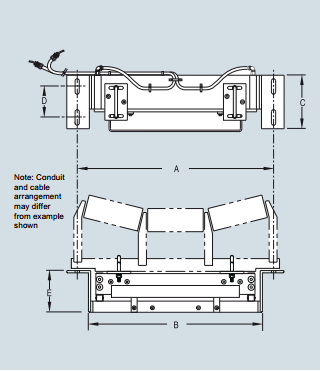

The MSI is installed in a simple drop-in operation and may be secured with just four bolts. An existing idler is then attached to the

MSI dynamic beam. With no moving parts, maintenance is kept

to a minimum, with just periodic calibration checks required.

Milltronics MMI belt scale

Milltronics MMI belt scale consists of two or more MSI single

idler belt scales installed in series. It provides high accuracy

continuous in-line weighing on a variety of products in primary

and secondary industries. The MMI system is proven in a wide

range of tough applications from extraction to power generation,

iron and steel, food processing and chemicals. The MMI is suitable for monitoring such diverse products as fertilizer, sand,

grain, flour, coal, or sugar.

The MMI’s proven use of parallelogram-style load cells results in

fast reaction to vertical forces, ensuring instant response to

product loading. This enables it to provide outstanding accuracy

and repeatability even with uneven or light loading, short idler

spacing and fast belt speeds. Operating with Milltronics BW500

or SIWAREX FTC integrator (for custody transfer applications),

the MMI provides indication of flow rate, total weight, belt load

and belt speed of bulk solids materials on a belt conveyor.

A speed sensor monitors conveyor belt speed for input to the integrator.

The MMI is installed in a simple drop-in operation and may be

secured with just eight bolts and existing idler sets, secured to

the dynamic beam. With no moving parts, maintenance is kept

to a minimum, with just periodic calibration checks required.