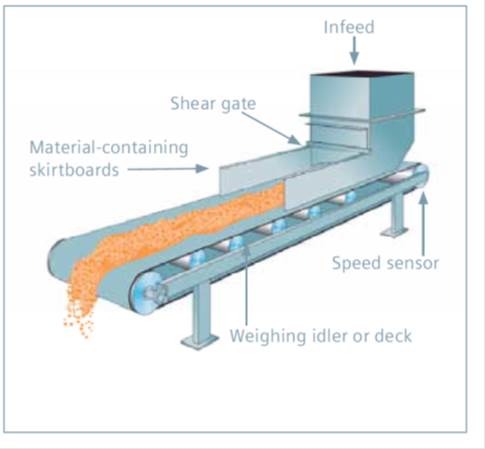

분.입체의 정량 이송 및 공급을 하는 장비로서 크게

컨베어 본체, In-Out Chute, Weighing Device, Speed Sensor

Motor, Inverter, PID Controller로 구성됩니다.

외부 설정값에 따라 벨트의 속도를 정밀 제어하여 원료의

투입량을 실시간으로 제어할 수 있습니다.

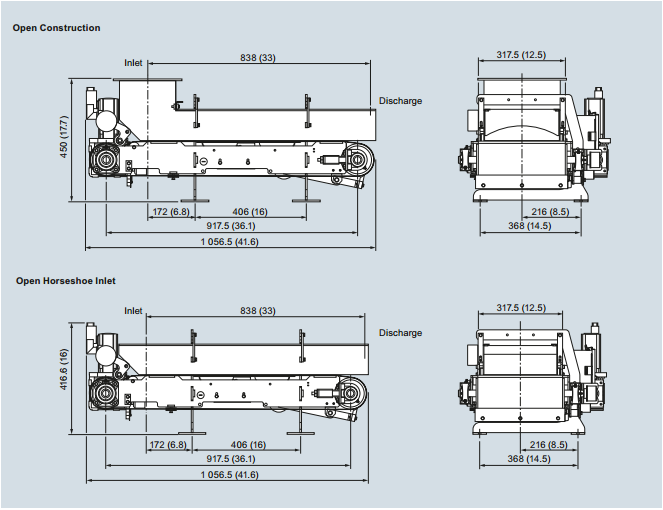

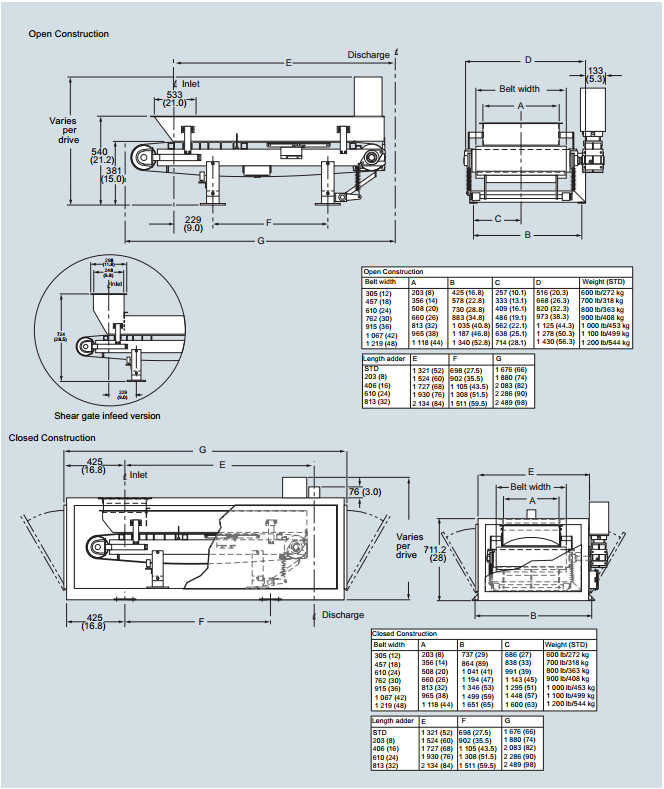

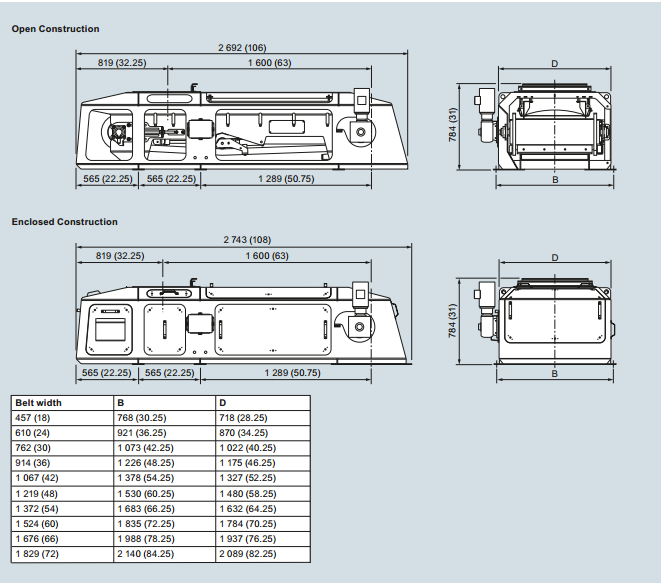

원료의 형상 및 최대 투입량에 따라 벨트폭 및 벨트의 종류가

정해지며 벨트의 두께가 얇을수록 정밀도가 향상되는

특징이 있습니다.